About

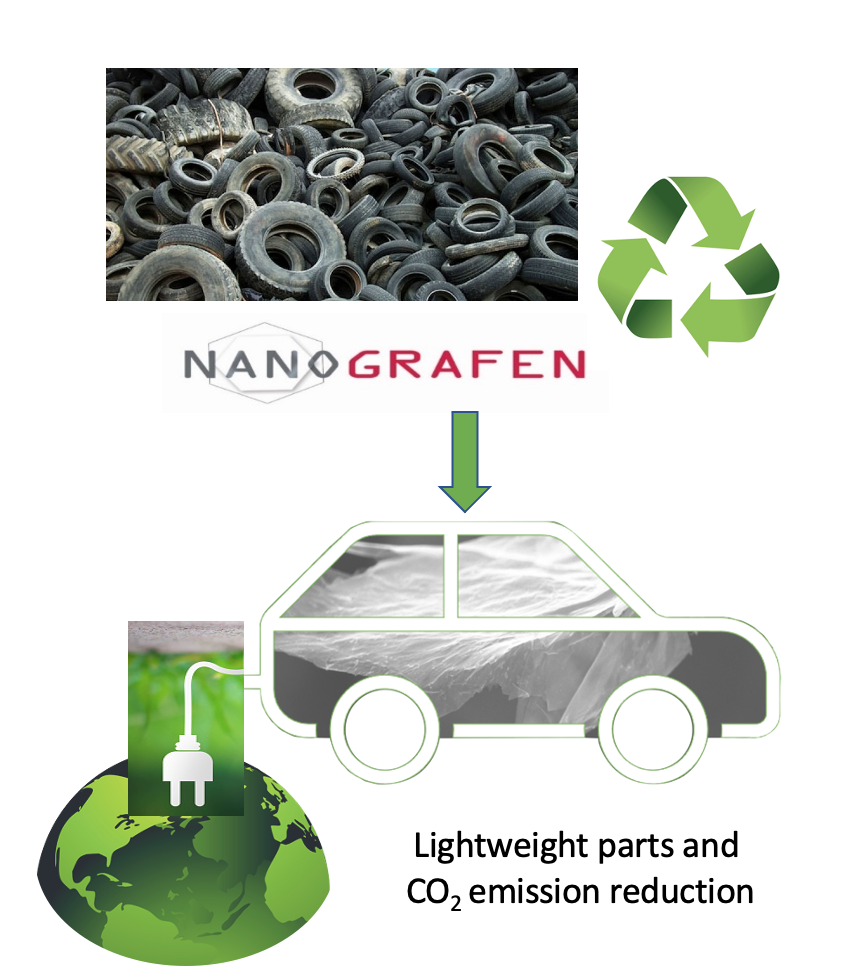

NANOGRAFEN is an innovative R&D company established in 2013 by scientists from Sabanci University and Inovent Company which is seed fund company, fully owned subsidiary of Sabanci University. Nanografen lowers the cost of graphene by using waste tire as a starting material by applying recycling and upcycling technology for mass production in plastic industry. Nanografen has a partnership with one of Turkish Pyrolysis Factories (GAN Pyrolysis) and established a pilot production line in Biga Organized Industrial Zone/Canakkale with the capacity of 2 ton/month. Nanografen Co is the only company that produce graphene from waste tires in plant scale around the world. This graphene can be used as a reinforcing agent at very low loadings in plastics to improve mechanical properties of the target parts in automotive and white goods. Also, Nanografen is developing cost-effective and light-weight automotive plastic composite parts with co-operation of Renault. Nanografen is an official material supplier of Renault together with Ravago (November 2021) and they develop OEM certified masterbatch to reduce glass fiber and mineral amount in polypropylene based interior and exterior parts.

Vision

AOur priority is to understand the current and future needs of plastic industry and R&D centers and provide high quality solutions and services to the customers, bring the innovation in composite technology and lightweighting applications, and enhance thermoplastic market by producing value-added products.

Mission

Nanografen offers robust, reliable, cost-effective and fast processes for upscaling graphene, improve thermal stability and mechanical properties of composite materials by using graphene in polymer matrix and provide significant weight reduction in materials. Nanografen addresses the needs of automotive, aerospace, white goods, and composite sectors by providing lightweightening and cost-effective reliable solutions and adopting eco-design and a circular economy approach with CO2 emission reduction.